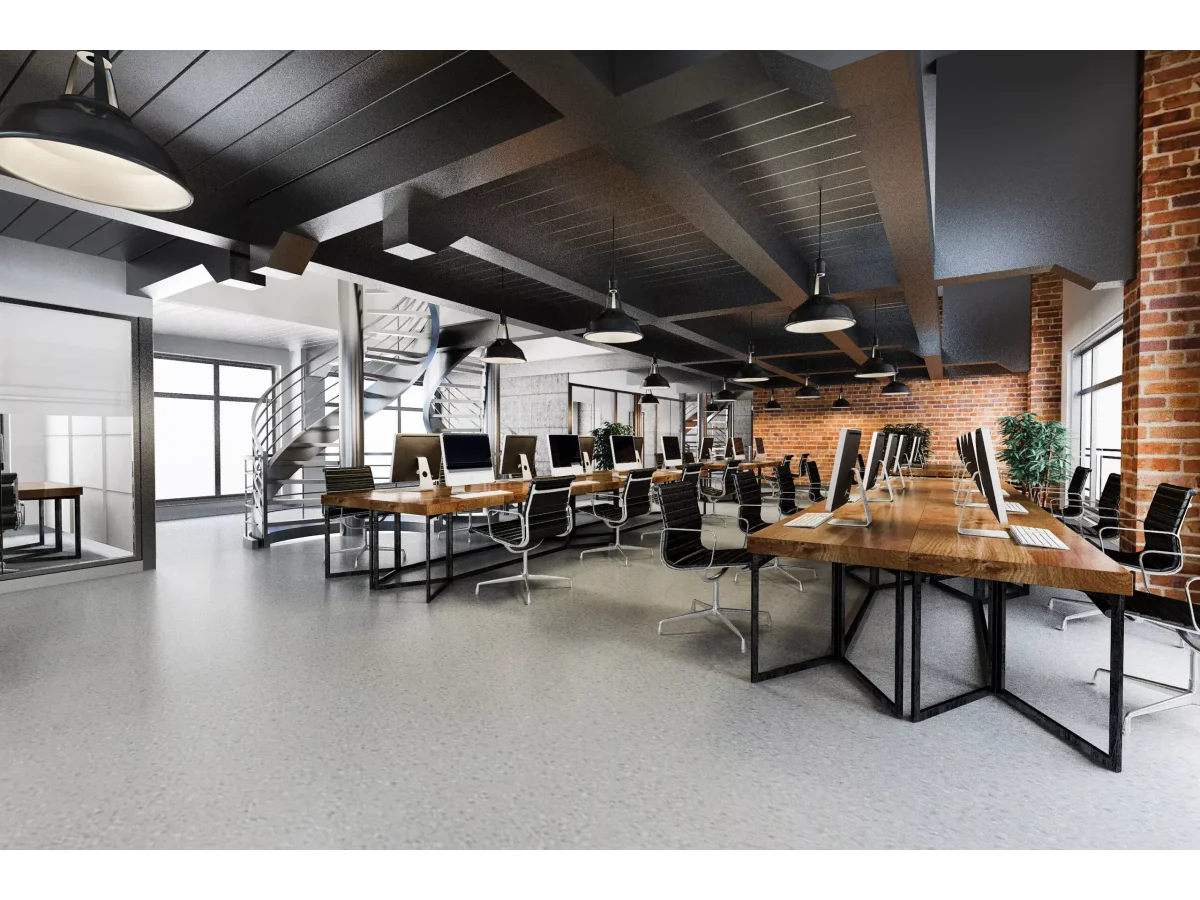

Loft offices as a showcase of modern technology

Older people may recall the acetylene generators used in Soviet times for gas welding. These generators generated high-temperature gas directly on-site from solid pieces of calcium carbide, which gradually converted to calcium carbide hydroxide under the influence of water poured into the reactor. This equipment was very bulky and time-consuming to operate. The same can be said of portable step-down transformers for manual arc welding, which could only step down the line voltage to increase the current to the level necessary to maintain a stable arc. Older people may also recall the student desks used in those days for furnishing school classrooms, whose support frames were assembled from thick-walled pipes, making them excessively heavy and resulting in an excessive consumption of valuable raw materials during their production. Over the past several decades, electrical engineering has achieved the greatest progress of any industry, which, surprisingly, has also borne fruit in furniture production. Advances in semiconductor technology and the discovery of new effects by physicists have enabled the creation of new welding equipment with far greater capabilities than those used in the last century. It's now easy to create reliable welds even when joining thin-walled steel sections, as demonstrated by some contemporary furniture designs. These highly popular loft offices are a clear example of this, since their production uses steel components that have replaced wooden ones.

This replacement provided the new type of product with several significant advantages:

Frames and supporting components made from profiles are much stronger and can withstand increased mechanical loads. This prevents the square or rectangular thin-walled tubes themselves from deteriorating, nor does it weaken the connections between them. Products made from these tubes are capable of faithfully serving their owners for many decades without any visible changes to any part of the structure.

Due to excellent resistance to bending deformation, there is no need to increase the width or cross-sectional area of horizontal elements, allowing for the weight of the product to be reduced to the minimum possible for this type of structure. This simplifies loading and handling within buildings and spaces, and reduces the cost of furniture products by reducing the materials used in their production.

It becomes possible to construct individual parts as frames with ample openings instead of solid pieces of particle board. In addition to the advantages listed above, this approach facilitates the maintenance of both the furniture itself and the space it occupies, significantly reducing the workload on cleaning staff.

Thus, loft offices make it possible to cope with many problems that until recently were considered fundamentally insurmountable.

Items included in loft office furnishings

Loft offices can be furnished with up to a dozen different items, primarily the desks, chairs, and armchairs necessary for setting up any workspace. Cabinets and shelving for storing documents and various accessories are also common. Two deserve special mention.

Dressing rooms

In offices and lobbies, there's often a need for a place for staff and visitors to change their clothes on a daily basis. Loft-style dressing rooms are increasingly being used for this purpose dressing rooms In addition to the advantages noted above, the use of multiple hollow metal sections in structures adds another advantage: a more efficient use of available storage space, ensuring that items don't stain others and that each item is kept in the most favorable conditions for careful storage.

Shelves

If you want to realize the creative ideas of designers to create an attractive interior in a room, various geometric shapes can be useful shelves They can serve as stands for pots with indoor plants or decorative ornaments placed at a large distance from the floor.

Write a comment